Corrosion protection specialist

About COREXCO

COREXCO is a company specialising in cathodic protection and corrosion prevention for buried or submerged metal infrastructures.

We operate mainly in the field of cathodic protection and corrosion prevention for buried or immersed metal structures. Our services are aimed in particular at the oil and gas, shipbuilding, nuclear power plant, pipeline and other industries where corrosion prevention is crucial.

Our services and solutions:

- Design and construction

- Inspection and maintenance

- Laboratory and R&D

- Product sales

We offer a wide range of products to protect steel structures against corrosion: anodes, electrodes, coke backfill, cyclic switches, current rectifiers, measuring equipment, insulating joints, special cables, etc.

We are at the service of private individuals, professionals and local authorities.

Expertise and experience:

Our team is made up of CEFRACOR-certified engineers specialising in cathodic protection.

COREXCO thus benefits from recognised expertise in the field of cathodic protection, with a team of qualified engineers with extensive experience in the fight against corrosion. Their know-how enables them to meet the specific needs of each project, ensuring effective and durable solutions.

You can count on our dynamic team to carry out all the installation work, as well as analyses, checks, measurements and maintenance.

Values and commitment:

The company is committed to providing high-quality cathodic protection solutions, with a focus on innovation, reliability and customer satisfaction. COREXCO aims to minimise the impact of corrosion and contribute to the sustainability of industrial and public infrastructures.

We are the professionals you need to guarantee the durability of buried and immersed structures.

COREXCO MARINE

In response to the growing needs expressed by our customers, we decided to create COREXCO-MARINE, a structure dedicated to the manufacture and marketing of sacrificial anodes for pleasure craft.

Its zinc anode foundry and machining workshop can meet the technical requirements and specific needs of each customer.

COREXCO-MARINE is able to supply more than 500 references of high-quality anodes (zinc, magnesium and aluminium indium).

The company specialises in cathodic protection and corrosion prevention for marine and offshore structures. Its services are aimed at the maritime industries, in particular shipbuilding and shipyards, as well as boat repairers.

Services and solutions:

Foundry: The company manufactures sacrificial anodes specifically adapted to marine conditions in its foundry based in the Lyon region.

Consultancy: The company offers consultancy services to help customers choose the best marine corrosion protection solutions.

Values and commitment:

COREXCO-MARINE is committed to providing high quality cathodic protection solutions for marine structures, with a focus on innovation, reliability and customer satisfaction. The company aims to minimise the impact of marine corrosion and contribute to the sustainability of maritime and offshore infrastructures.

The company knows that it is essential for its customers to receive fast, efficient responses to their requests. It makes every effort to meet the specific needs of each customer as quickly as possible, in order to establish a solid relationship based on mutual trust.

Contact:

- Website: https://www.corexco-marine.fr/

- Address: 4 Rue des Frères Lumière - 69680 CHASSIEU - Telephone number: 04 74 71 11 33

- Email: fleurg@corexco-marine.fr

DEFINITIONS & EXPLANATIONS

The basic principle of corrosion

Corrosion is the principle by which metal seeks to return to its natural state by losing electrons and combining with electron-accepting components in its environment. This is an electrochemical process known as oxidation-reduction. In nature, iron exists in the form of an oxide, the orange compound commonly known as rust.

The ability of a metal to corrode depends on how easily it loses electrons and the environment in which it is found (humidity, temperature, aggressiveness, etc.). This phenomenon alters the mechanical properties of the metal and can cause structural failure.

Cathodic protection

Cathodic protection is commonly used in various industries, including the oil, gas, marine and urban infrastructure sectors, to extend the life of metal equipment and minimise the maintenance costs associated with corrosion.

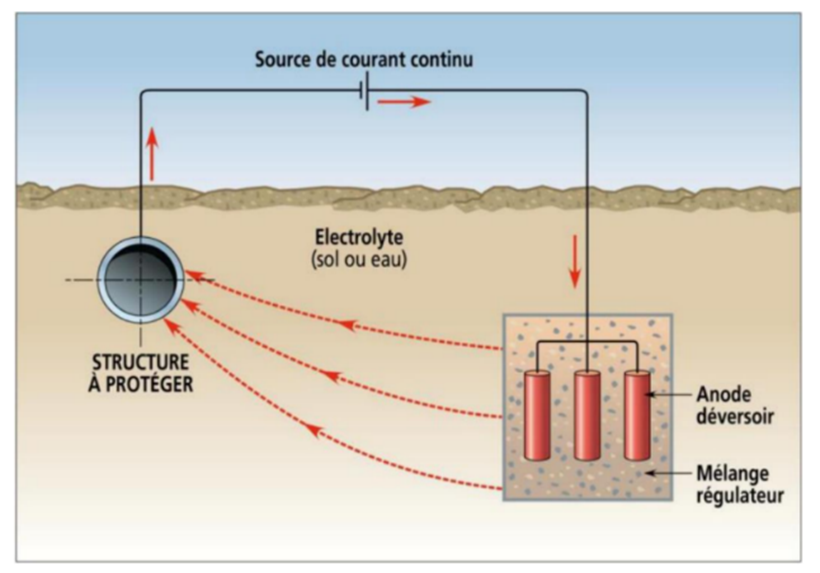

It is a technique used to slow down the rate of corrosion of submerged or buried metal structures. It involves lowering the potential of the metal to be protected to bring it into its immunity zone (Pourbaix E-pH diagram).

The mandatory conditions for implementing a cathodic protection system are: a conductive medium, an electrical connection and two metals.

There are two types of cathodic protection: "passive" and "active". At COREXCO, we focus on active protection.

Passive protection

Passive protection is used to protect a structure by creating an electrical barrier between the metal and the exterior using a coating. (paint, polyethylene, coal tar, grease).

Active protection

Active protection preserves the external surface of buried or immersed steel structures by slowing down the corrosion process.

This can be achieved using two types of system:

Galvanic current: Anodes with a standard potential lower than the metal to be protected

Impressed current: Anodes coupled to a DC voltage generator that imposes a potential difference between the two metals.

Measurement and control (electrodes)

Reference electrodes are used to check and monitor the cathodic protection of metal structures. They are useful in several ways:

- Measurement of electrochemical potential: Reference electrodes are used to measure the electrochemical potential of the protected structure in relation to a stable reference point. This helps to determine whether the structure is sufficiently protected against corrosion.

- Assessing the effectiveness of cathodic protection: By comparing the measured potentials with known reference values, engineers can assess the effectiveness of the cathodic protection system.

- Adjustment of the protection system: The data obtained is used to adjust the parameters of the cathodic protection system. This ensures that the protection remains optimal despite changes in environmental conditions or structural properties.

- Anomaly detection: Reference electrodes help to identify areas where cathodic protection may be insufficient or excessive.